TRANSFORM: Driving Profitability into Propane Distribution

September 14, 2020The benefits of using tank monitors with forecasting, ticketing, routing, and truck computers to drive distribution efficiency and improve customer engagement are well understood. However, achieving reduced costs and customer terminations requires management awareness of inefficiencies, staff engagement in a change program, courage to operationalize savings by retiring bobtails, and, the focus of this article, intimate integration across systems and applications.

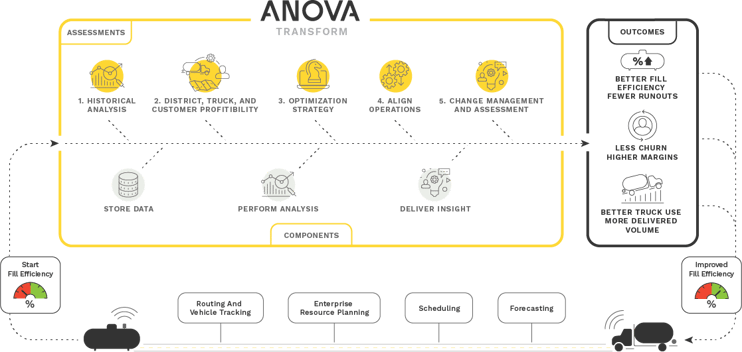

Introducing Anova TRANSFORM Solution:

A comprehensive software and service to drive productivity and profitability.

Tank monitoring’s total cost of ownership continues to fall while reliability and battery life continue to rise. Total cost of ownership includes capital depreciation, monthly fees, and installation cost. While a cellular-based system is cost effective for up to 30% of tanks, we are entering the industry 4.0 era, facilitating a trend towards automation and data exchange with Internet of Things (IoT) costs falling further, driving effective ROI for more than 60% of propane tanks.

The Need for the Delivery Efficiency

At the same time, the need for the delivery efficiency is increasing. The number of gallons supplied has been contracting each year; the cost of delivery has increased; demand and weather patterns have become less predictable; and the cost of propane has grown more volatile with changes in global demand. For propane marketers, reducing the cost of delivery and customer churn for increased profitability is critical to meeting these challenges.

Anova Expertise

Anova has accumulated more than 6 million propane delivery records working with propane distributors on logistics transformation. This data shows an average fill without monitoring of 42% of water volume and an average fill with monitoring of 53%. With better integration between monitors, back-office software, and onboard truck computing systems, an average fill of 60% with improved truck productivity (e.g., 3000-plus drops per year) should be achievable. At that point, propane marketers can dramatically reduce their costs by operating fewer bobtails and needing fewer drivers, a scarce resource.

Tools for Change

Anova recognizes the opportunity to reduce the workload of operations staff, improve fill rates, increase truck productivity, and create a platform for new consumer engagement models through better integration across the systems propane distributors rely on. We have been quietly advocating for the development of advanced integration standards for several years and would welcome the opportunity of working with other vendors, including competitors, to agree upon and start the realization of a set of standards that would benefit our mutual customers.

60% Average Fill Target

Anova Transform is based on the realization that, in order to achieve the goal of 60% average fill and also increase profits, a propane distributor need to do more than simply deploy a monitor to a propane tank. Only through alignment of 3 fundamental pillars of the business (Business Strategy, E-Logistics & Operations and IT Infrastructure) towards a common objective can the business achieve this goal.

3-Step Transformation Stages

Transform can be viewed not as a stand-alone analysis application but instead a system which is built upon Anova’s powerful analytics platform and change management services.

Transform takes the propane distributor on journey to increase distributor profit in three major stages:

- Stage 1: Increase per drop fill efficiency by deploying monitors to lowest performing accounts

- Stage 2: Reduce customer churn and improve account margins by leveraging monitor data and integrating to your back-office software

- Stage 3: Improve per truck productivity & optimize fleet capacity by analysing monitor impact and truck performance + improving routing and truck distribution.

Transform allows companies of any size to analyze core parts of their propane delivery. It will allow for an increase in gallons delivered, a decrease in fleet size, and an over rise of productivity. Customer retention will rise while the amount of runouts will fall.

Easy.

Reliable.

Worth it.

Take bold steps, faster

By choosing systems with a long life span and a commitment to back office integration beyond today’s typical exchange of level data, propane marketers can maximize the benefits of tank monitoring, as well as their investment in back-office systems and truck computers, to leverage what is possible today while simultaneously planning for a future in which the IT systems carry more of the workload. This will further reduce the number of runouts and improve engagement with the end-gas consumers, generating stronger customer loyalty, and potentially halving the direct cost of delivering propane.

For more information on Anova TRANSFORM to contact Anova:

Visit pages.anova.com/transform